In the suspension system, because elastic elements are impacted to cause

vibration, the shock absorber and elastic elements are installed in

parallel in the suspension in order to improve driving smoothness of

automobiles; in order to reduce vibration, the shock absorbers widely

used in the automotive suspension system are often hydraulic shock

absorbers, its working principle is that: when the relative motion

between the automobile frame (or automobile body) and the driving axle

occurs due to vibration, the piston in the shock absorber moves up and

down, the oil in the cavities of the shock absorber repeatedly flows

from one cavity to another cavity via different holes, at this time, the

friction between the hole walls and the oil and between oil molecules

form the damping force, and the vibration energy of the automobile is

converted into heat energy of the oil and then absorbed by the shock

absorber and emitted to the atmosphere. Under the condition of the same

total sectional area of oil channels, the damping force of the shock

absorber increases or decreases along with the increase or decrease of

the relative motion speed of the automobile frame and the driving

axle(or wheels), and is related to viscosity of the oil. The shock

absorber and the elastic elements take the task of buffering impact and

reducing vibration. When the damping force is too big, the elasticity of

the suspension will get bad, even the connecting piece of the shock

absorber is damaged, so that the contradiction between the elastic

elements and the shock absorber must be solved.

(1) In the

compression stroke (the driving axle and the automobile frame are

closing to each other), the damping force of the shock absorber is small

so as to give a full play of the elastic action of elastic elements to

buffer impact. At this time, the elastic elements play a leading role;

(2)In

the stretching stroke (the driving axle and the automobile frame are

getting away from each other), the damping force of the shock absorber

should be big, so that the vibration can be reduced quickly;

(3)When

the relative speed between the driving axle (or wheels) and driving axle

is too high, the shock absorber should automatically increase the flow

rate of the oil, so that the damping force is kept in a certain range so

as to avoid too big impact load;

The telescopic shock absorber is

widely used in the automotive suspension system, and the shock absorber

which has the shock absorbing effect in both compression stroke and

stretching stroke is the bi-directional action type shock absorber; in

addition, some new shock absorbers including gas filling type shock

absorbers and damping force adjusting shock absorbers are also used.

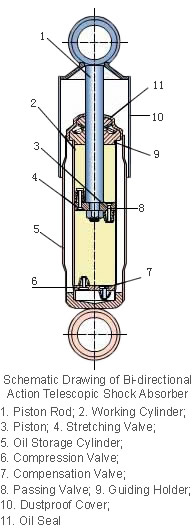

The

working principle of the bi-directional action telescopic shock

absorber is that: in the compression stroke, namely the automobile

wheels move close to the automobile body, the shock absorber is

compressed, the piston 3 of the shock absorber moves downward, the

volume of the lower cavity of the piston is decreased, the oil pressure

rises, the oil flows to the cavity (upper cavity) above the piston via

the passing valve 8, and the partial space of the upper cavity is

occupied by the piston rod 1, so that the increased volume of the upper

cavity is less than the decreased volume of the lower cavity, some oil

pushes the compression valve 6 and flows back to the oil cylinder 5, and

the oil-saving action of these valves forms the damping force against

the compressed motion of the suspension; in the stretching stroke of the

shock absorber, the wheels are relatively away from the automobile

body, the shock absorber is stretched, the piston of the shock absorber

moves upward, the oil pressure of the lower cavity of the piston rises,

the passing valve 8 is closed, the oil in the upper cavity pushes the

stretching valve 4 and flows to the lower cavity; and because of the

existence of the piston rod, the oil flowing from the upper cavity is

not enough to fill up the increased space of the lower cavity, so that a

certain vacuum degree is generated in the lower cavity, the oil in the

oil storage cylinder pushes the compensation valve 7 and flows to the

lower cavity for supplement, and the throttling action of these valves

forms the damping force against the stretching motion of the suspension.

Because

the designed rigidity and pre-tightening force of the stretching valve

are greater than those of the compression valve, under the same

pressure, the total sectional area of the stretching valve and the

channels of the corresponding normal open gaps is less than that of the

compression valve and the channels of the corresponding normal open

gaps, so that the damping force generated in the stretching stroke of

the shock absorber is more than that generated in the compression stroke

of the shock absorber, and the aim of quickly reduce the vibration is

achieved.

The following drawing shows the structural drawing of front

and rear suspension shock absorbers of an automobile. Its working

principle has been introduced above.

- Products

-

- -Air Suspension Strut

- -Electronic Shock Absorber

- -Electronic Air Suspension

- -Cartidge shock absorber

- -Monotube shock absorber

- -Double-tube shock absorber

- -Modified car shock absorber

- -Assembly shock absorber

- -Truck shock absorber

- -Steer damper

- -Golf car shock absorber

- -Suspension Coil Spring

- -Lifted or Lowering Spring

Yangzhou Focus Shock Absorber Co., Ltd.

Technological leadership and innovative quality improvement

Yangzhou Focus Shock Absorber Co., Ltd.

Technological leadership and innovative quality improvement

Yangzhou Focus Shock Absorber Co., Ltd.

Technological leadership and innovative quality improvement